Description

Here's a breakdown of its characteristics:

- Wear Protection: The primary function of the additive is to form a protective film on the metal surfaces within the hydraulic system, which helps prevent friction and reduces the chances of wear, especially in high-pressure environments.

- Oxidation Stability: The additive may also help improve the oil's resistance to oxidation, which can cause the oil to degrade and lose its effectiveness over time. By preventing oxidation, the oil maintains its performance for a longer duration.

- Corrosion Inhibition: It may include agents that prevent rust and corrosion formation, which can be critical in systems exposed to moisture or in harsh environments.

- Viscosity Control: Some antibear additives help maintain the desired viscosity of the hydraulic oil, ensuring it flows efficiently and protects the system under various operating temperatures.

- Enhanced Performance: Depending on the formulation, the additive can also provide other benefits like improved foam control, demulsibility, and air release, ensuring that the hydraulic system operates smoothly without interruptions.

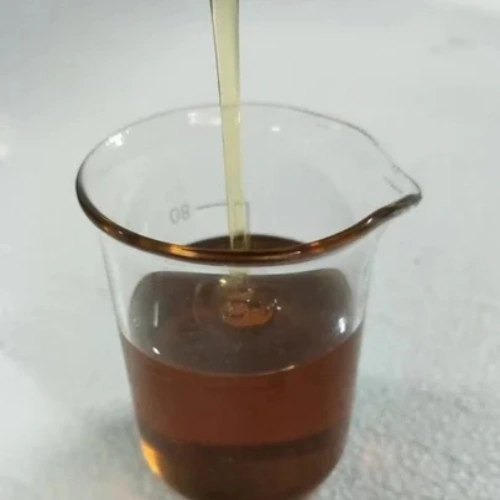

- Brown Color: The "brown" color typically comes from the particular combination of base oil and additive components used in the formulation. It's a visual indicator that may distinguish it from other additives, which could be clear or a different color.

The use of antiwear hydraulic oil additives is crucial in industries that rely on hydraulic systems, such as manufacturing, construction, and automotive, to ensure the machinery operates efficiently and experiences minimal wear.

Additional Information:

- Delivery Time: 3to4days

- Packaging Details: DRUM